Keywords: Placement Machine, AC Servo, Motion Control Card

1.Overview

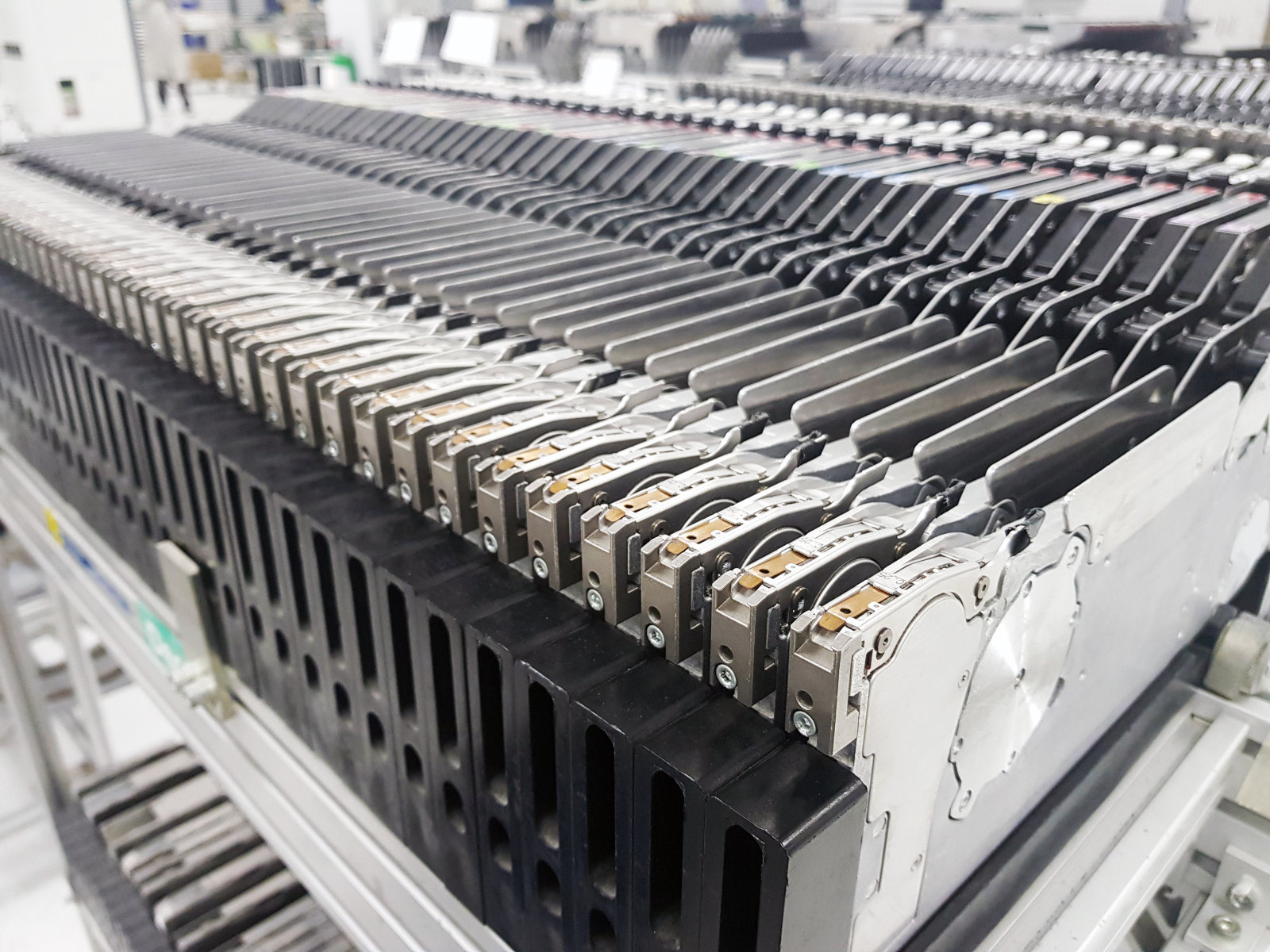

The SMT component Placement machine is used to place components automatically in high speed, high precision ,which is very complicated and a very important process after dispensing machine and printing machine. The performance requirements become higher and higher with the size of electronic components becomes smaller and smaller.

The main features of SMT placement machine

Visual recognition technology: the visual recognition software with continuous rapid shooting and positioning for optical image capture , positioning and flight alignment;

Built-in AOI detection function: SMT placement machine can check the quality of printing solder paste before mounting, and can check the accuracy of the mounted components after mounting ;

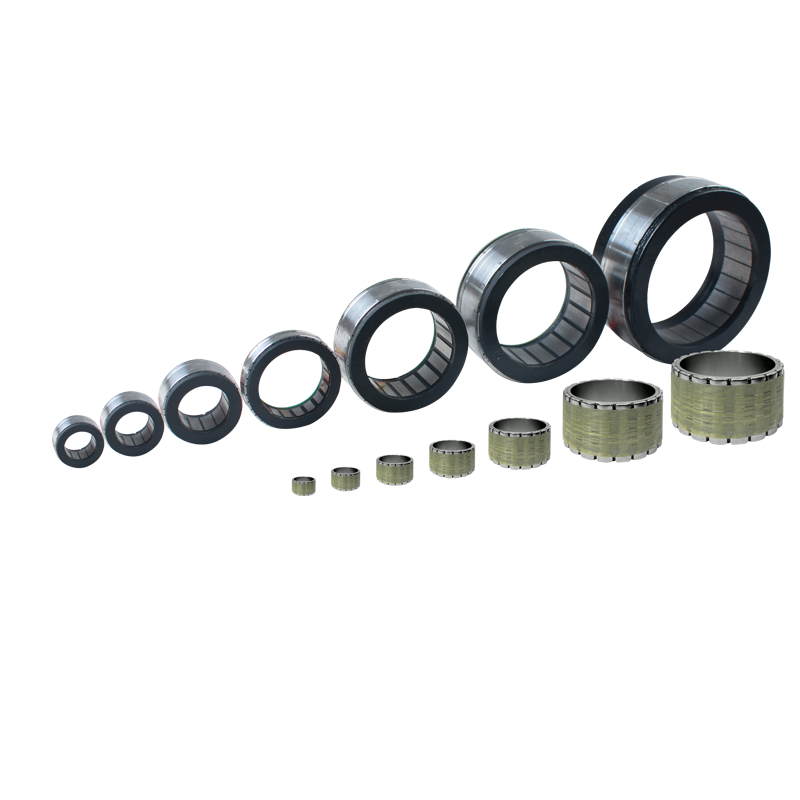

IC components with 0402-40mm size can be mounted with the fastest patch speed up to 15000cph ;

a variety of components are supported : resistors, capacitors, IC, BGA, QFP, CFP& μ BGA;

2. System Configuration

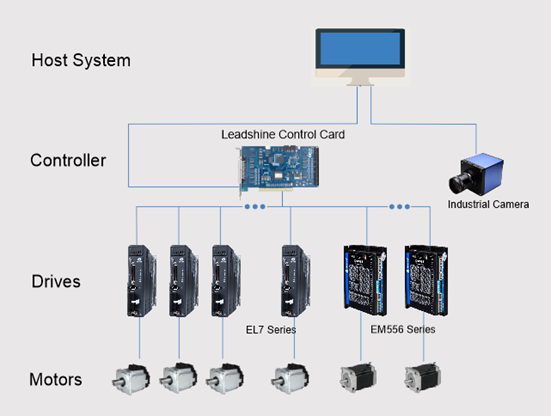

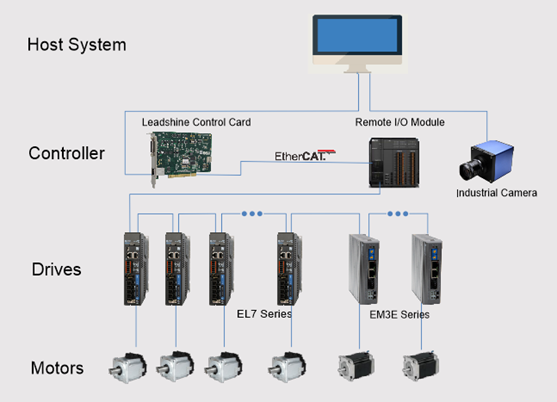

Leadshine can provide both pulse control type and network control type products solution

2.1 Pulse control type system configuration

2.2 Fieldbus control type (EtherCAT) system configuration

3. Leadshine solution advantages

Leadshine solution includes motion control card + AC servo Sets + stepper products for customer’s different kinds of requirements.

Leadshine solution optimizes the movement process of online position shifting, flying shot, instruction buffer, gantry to shorten the movement cycle, improve the positioning accuracy and make the equipment more efficient.

The motor with 23bit encoder make the mounting movement more accurate and more smooth.