Abstract: Leadshine provide a whole solution with HMI+PLC+AC Servo/Stepper to make sealing process in a more elegant transition.

Keywords: Servo ,HMI, PLC

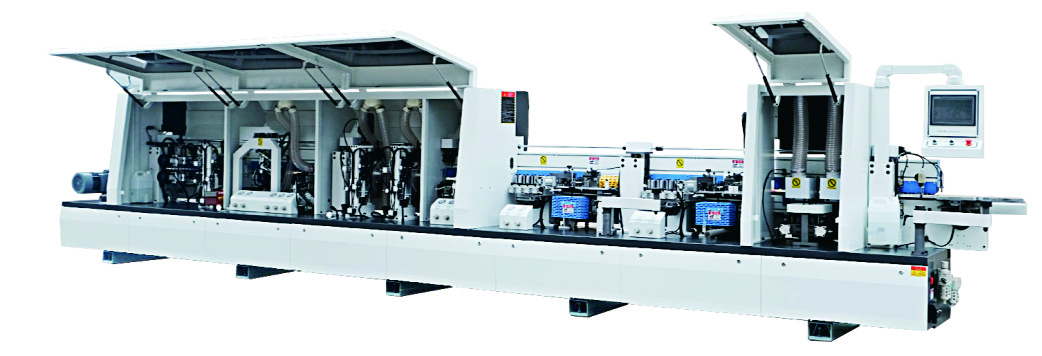

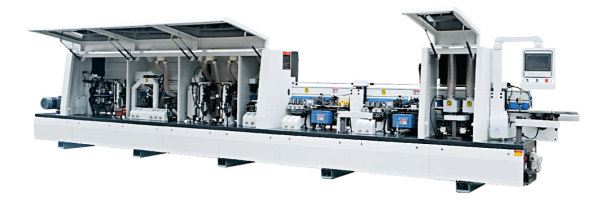

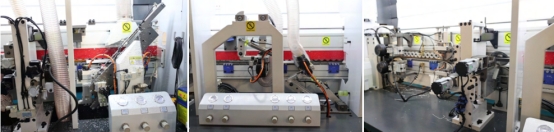

1. Equipment Introduction

Edge bander machine is a kind of wooden processing machine that replaces manual edge bander procedures: conveying - gluing and pasting - cutting - front and rear end trimming - upper and lower trimming - upper and lower fine trimming - upper and lower scraping - polishing. Leadshine provide a whole solution with HMI+PLC+AC servo/stepper for edge bander machine to make all processing more easier and more flexible .

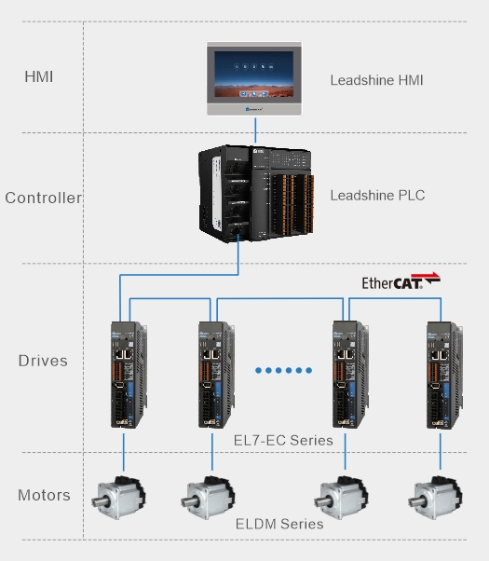

2. System Configuration

System Configuration for EtherCAT Fieldbus Servo Solution

System Configuration for RS485 Fieldbus Servo Solution

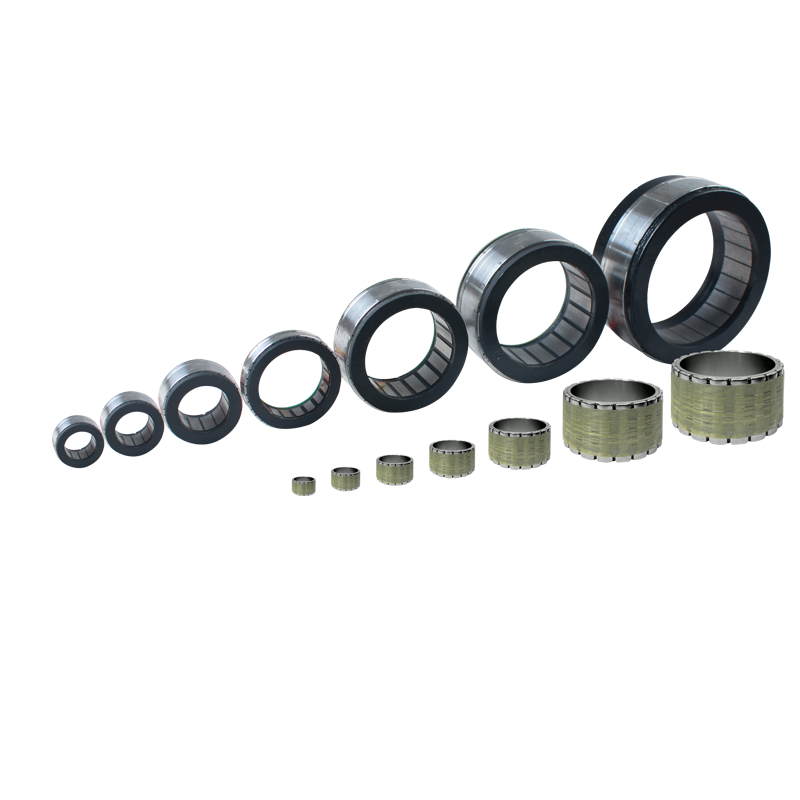

3. Products configuration

3.1 Solution with EtherCAT communication

Processing Steps | HMI/PLC | Servo solution |

Guide plant adjustment | LT2100E MC600 | EL7-EC series AC servo , 100w ,200w , 400w |

Pre-milling mechanism | ||

Double glue pot mechanism | ||

Front to back mechanism | ||

Fine repairing mechanism | ||

Trace trimming mechanism | ||

Polishing mechanism | ||

Automatic pressure beam positioning | EL7-EC series AC servo , 750w |

3.2 Solution with RS485 communication

Processing Steps | HMI/PLC | Servo solution |

Guide plant adjustment | LT2100E MP2-40MR | EL6-RS series AC servo , 100w ,200w , 400w |

Pre-milling mechanism | ||

Double glue pot mechanism | ||

Front to back mechanism | ||

Fine repairing mechanism | ||

Trace trimming mechanism | ||

Polishing mechanism | ||

Automatic pressure beam positioning | EL6-RS series AC servo , 750w |

4. Solution Advantages :

Abundant solution&experience : 10 years experience with closeloop stepper + AC Servo + HMI/PLC solution , leadshine keeps providing upgraded solution and professional support .

Leading algorithm : Customized NC processing function , powerful calculation and flexible configuration to make operation more efficient.

Stable and reliable products: customer can mange and standardize the whole solution with modular structure, easy assembly, strong universality .

Added value for customers :

Cost-saving and efficiency : automatic tool calibration with servo control saves debugging time and labor cost , make the edge banding process in a better result;

Network communication and data saved : Leadshine solution HMI+PLC+Servo +stepper with EtherCAT communication and absolute encoder make the the process more simple and the result easier to be saved ;

Powerful function and strong expansibility: The thickness of the edge banding strip can be switched easily and electronic cam are supported in control system for up to 32 axes.

Networking module: The Internet of things module can be added to the HMI. which make operation status of equipment can be monitored in real time via mobile terminal, and remote operation and modification of machine program are supported

5. Application Scenario

Front and back flush Profile tracking shaving