The EL6 Series of our AC servo drives, in particular, have been painstakingly designed to satisfy the exacting requirements of contemporary applications. Our sophisticated encoder technology, which greatly improves performance and precision, is a crucial feature that distinguishes our AC servo drives.

The Role of Encoder Technology in AC Servo Drives

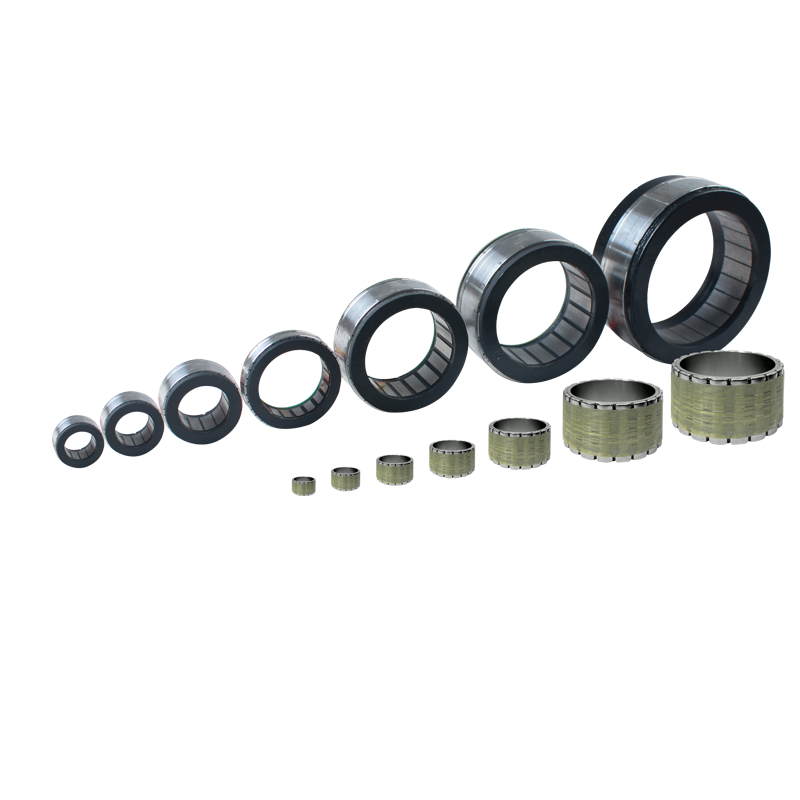

Encoder technology plays a vital role in the functionality of our AC servo drives. In essence, encoders provide real-time feedback regarding the position, speed, and direction of the motor. This feedback mechanism is essential for maintaining accurate control in various applications, from robotics to CNC machinery. Our EL6 Series incorporates high-resolution ABZ encoders with differential ABZ and OCZ output, allowing for the precise tracking of motor movement.

With 23-bits magnetic and optical encoders available, we ensure that every motion is executed with remarkable accuracy. This level of precision is especially crucial in applications where even the slightest deviation can lead to significant operational issues. By leveraging advanced encoder technology, our AC servo drives facilitate seamless integration into complex systems, optimizing overall performance and productivity.

Advantages of Using AC Servo Drives with Advanced Encoders

The advantages of implementing Leadshine's AC servo drives equipped with advanced encoders are numerous. Firstly, the enhanced feedback provided by our encoder technology allows for improved motion control, leading to smoother operation and reduced mechanical wear. As a result, businesses can enjoy longer equipment lifespans and lower maintenance costs.

Additionally, our AC servo drives feature impressive capabilities such as zero tracking control and vibration suppression with notch filters, both of which are made possible through accurate encoder feedback. These functions ensure that systems operate efficiently, minimizing disruptions and enhancing overall output quality. With user-configurable I/O settings and support for various communication protocols like Modbus RTU and EtherCAT, our AC servo drives offer unparalleled flexibility for different industrial environments.

Integrating Encoder Technology with DC Servo Drives

While this article primarily focuses on the importance of encoder technology in our AC servo drives, it is also worth noting how similar principles apply to our DC servo drives. Leadshine’s DC servo drives also utilize encoder technology to provide precise feedback, contributing to the overall efficacy of the system. However, the unique features of our AC servo drives, particularly in terms of enhanced control modes and encoder resolution, make them a standout choice for applications demanding high performance.

Conclusion

It is impossible to exaggerate the significance of encoder technology in Leadshine's AC servo drives. For a range of industrial applications, we provide unparalleled precision, dependability, and flexibility by incorporating encoders into our EL6 Series. The need for advanced motion control systems will only increase as industries continue to change. Put your trust in us to increase the efficiency of your automated processes.