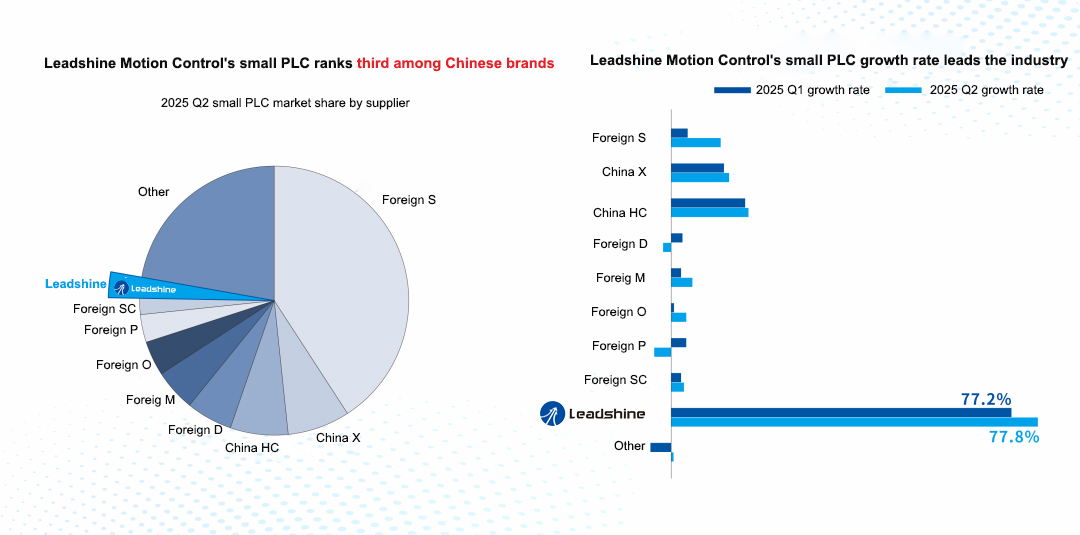

According to the latest statistics from industry monitoring agency MIR Rui Industry, the domestic substitution wave in China's compact PLC market accelerated in the first half of 2025. Leadshine maintained its industry-leading position with a remarkable 78% year-on-year growth rate, achieving a market share exceeding 3%. This performance further consolidates Leadshine's position among the top three domestic brands in the compact PLC sector.

Under the dual drivers of intelligent manufacturing advancement and domestic substitution, Leadshine continues to unleash growth momentum through three strategic dimensions:

01 Product Innovation: Dual-Series Strategy Builds Motion Control PLC Technology Fortress

Leadshine's compact PLC portfolio features two product matrices:

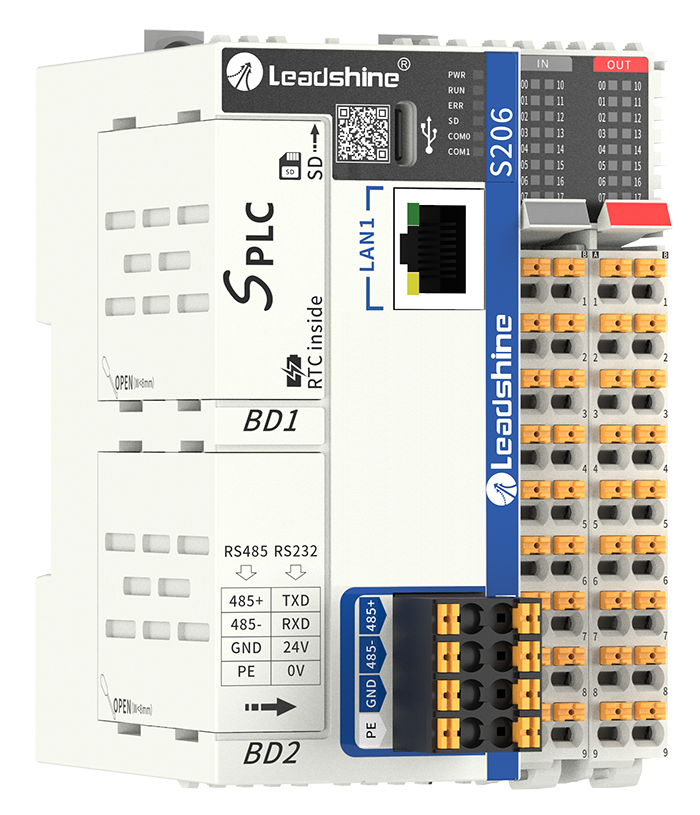

Ultra-Strong Motion Control S-Series

Breadboard-Style SCnU Series

Equipped with 4-core CPU and nanosecond-level multi-task processing technology, these PLCs demonstrate:

50% higher computing power compared to traditional PLCs

7ns instruction processing speed (industry-leading responsiveness)

This technological architecture establishes a competitive barrier in motion control precision and real-time performance, supporting complex industrial automation scenarios.

The S Series Super-Powerful Operation and Control PLC: Its ultra-thin design, with expansion modules as thin as 12mm, offers customers an ultimate space-saving experience. Tool-free wiring with large-diameter terminals increases wiring efficiency by 60%. Standard dual Ethernet ports and independent IP interfaces eliminate the need for external switches and enable fast device cascading. (The S6 Series comes standard with 64-axis EtherCAT bus control, making it suitable for multi-axis operation and control equipment in complex 3C assembly lines, lithium battery pack lines, and logistics cross-belts.)

The SC5U Series PLC supports up to 32 EtherCAT bus axes and features 4-12 200K high-speed pulse axis control. Its high overload current, horizontal heat dissipation, and "breadbox" screw-type terminal blocks make it the preferred solution for traditional industries such as packaging, woodworking, basic electronics, and special machine tools.

02 Solution Breakthrough: Winding + Robotics-like Industry Process Algorithms Continue to Lead

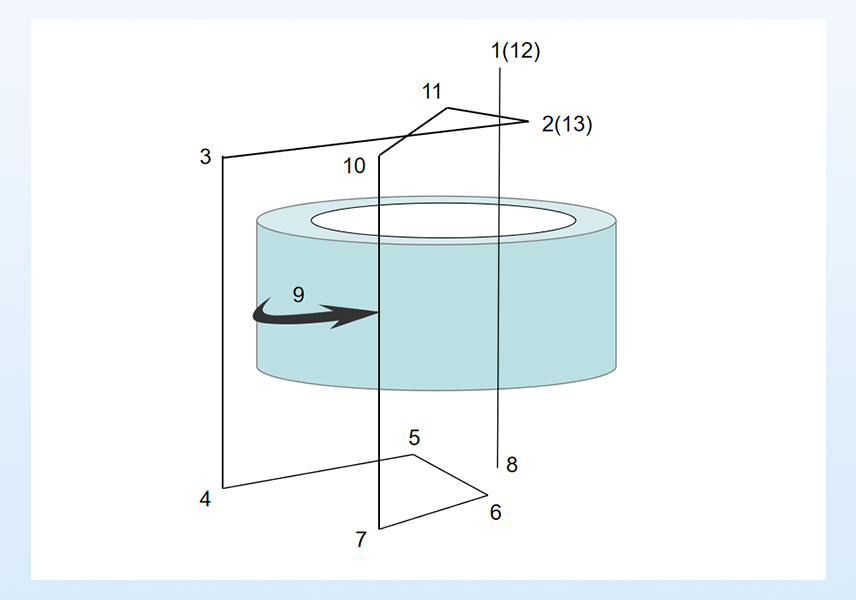

Winding Industry: Leadshine has packaged a magnetic winding process function block. Through the deep collaboration of electronic CAM and core winding algorithms, it addresses pain points such as low equipment efficiency, uneven wire routing, and unstable winding. This improves equipment efficiency by 30% and achieves a yield rate exceeding 99.9%.

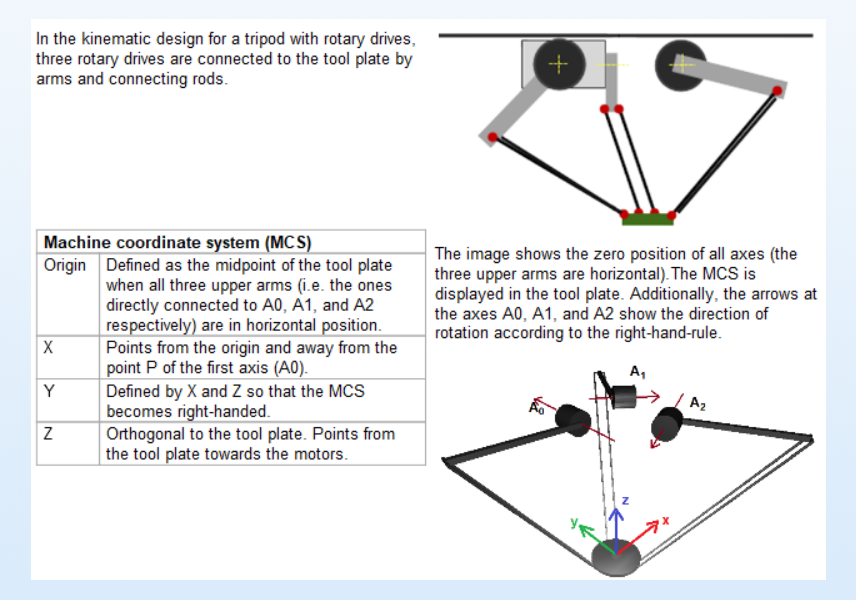

Robotics-like Industry: Leadshine's proprietary Delta Robot trajectory planning algorithm, integrating vision guidance and feedback control technology, achieves a positioning accuracy of ±0.1mm. In high-speed sorting scenarios, it achieves a cycle time of 0.6 seconds per piece, a 30% improvement in efficiency compared to traditional modules. The system includes a built-in robot-specific process library and pre-configured forward and inverse kinematic analytical models. Engineers only need to configure basic mechanical parameters to automatically generate motion trajectories, significantly reducing the equipment development cycle from the traditional 15 days to 3 days.

03 Market Layout: Building a Global PLC Ecosystem

Ecosystem Coverage: Leadshine's newly launched Leadsys V3.2 programming platform (compliant with IEC 61131-3) achieves multiple technological breakthroughs:

1. Intelligent exception troubleshooting accurately identifies common errors such as array out-of-bounds and division by zero, reducing program debugging time by 40% ↓

2. Innovative Chinese label communication technology improves configuration efficiency by 80% ↑

3.Address retention mode, combined with the data snapshot function, improves data migration and backup efficiency by 50% ↑

4. Intelligent project version matching technology enables firmware upgrades in 3 seconds, improving overall development efficiency by 50% ↑

Targeting the small stand-alone device market, Leadshine's independently developed LeadStudio programming platform utilizes a compiled architecture, achieving instruction execution speeds 80 times faster than traditional interpreted PLCs.

1. The ladder diagram incremental paste function supports automatic component numbering, improving programming efficiency by over 50% for identical logic. ↑

2. Online editing, combined with TRACE oscilloscope real-time monitoring, reduces equipment debugging downtime by 70%. ↓

3. Compatible with Japanese ladder diagram programming practices, customizable FB/FC encapsulation functionality shortens equipment development cycles by 30%. ↓

Overseas Expansion: We jointly developed an intelligent seeding wall project with a leading logistics and warehousing equipment company. The project has been installed and deployed at multiple logistics sites worldwide, achieving fully automated sorting speeds of up to 10,000 pieces per hour with 99.99% accuracy, ranking among the world's top performers.

Customer Service Process Streamlining: Leadshine's efficient process system transforms customer pain points collected through the ITR process into product optimization options through the OR process, driving next-generation product innovation and upgrades. Through the coordinated operation of the OR/ITR process system, the company has increased customer demand hit rate by 90% and customer issue response speed by over 60%.

Leadshine will continue to take customer needs as its anchor, and through easier-to-use development platforms and more practical solutions, work with many partners to promote domestic PLCs from "replacement" to "leading", and leave the mark of Chinese intelligent manufacturing in the global intelligent manufacturing landscape.