When we discuss precision motion control, we understand how crucial it is to match the right components with the right application. At Leadshine, we’ve spent years refining our technologies to better serve automation professionals around the world. Among our product offerings, two of the most frequently asked topics are about stepper motor sizes and finding the optimal cnc stepper motor for specific needs. By sharing our experience and technical understanding, we hope to make your selection process much more effective.

Understanding Stepper Motor Sizes for Industrial Applications

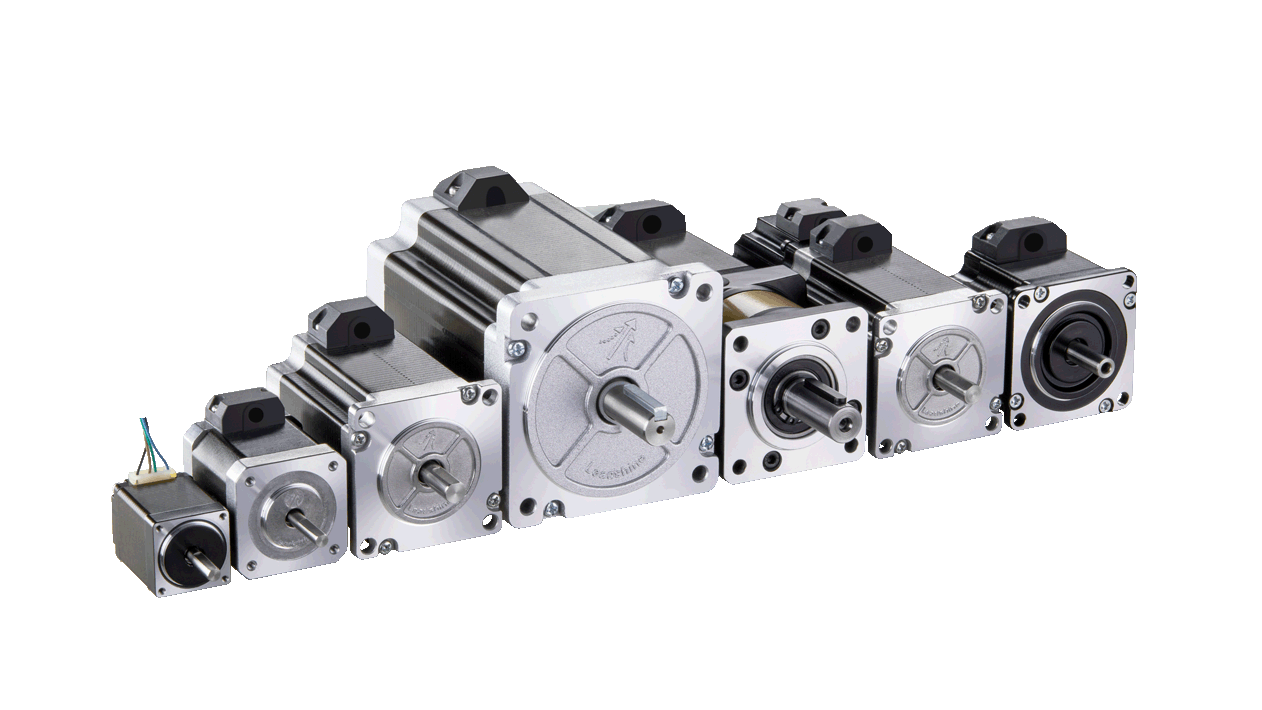

We often receive questions about how to choose the correct stepper motor sizes for different projects. This decision significantly impacts the motor's performance, efficiency, and lifespan. Our product lineup offers a wide range of stepper motor sizes, including NEMA 8 to NEMA 42, catering to a variety of torque and dimensional requirements.

Whether you're designing compact electronics or working with large-scale machinery, size matters—not just in terms of fit, but also in how it affects torque generation and thermal performance. A smaller motor may seem sufficient in early testing, but prolonged use under heavy loads could reduce its effectiveness. We encourage customers to think beyond initial dimensions and consider the full duty cycle and torque demands of their systems.

Optimizing CNC Performance with the Right Stepper Motors

Another area of frequent consultation is how to select a cnc stepper motor that meets precision demands without overcomplicating the system. At Leadshine, we specialize in engineering motors that are tailored for CNC applications—balancing reliability, resolution, and affordability. Our hybrid stepper motors, known for their accuracy and minimal noise, are widely used in CNC routers, engravers, and laser systems.

Selecting a cnc stepper motor isn’t only about choosing a torque rating or frame size. It’s also about ensuring compatibility with drives and controllers, evaluating heat dissipation, and making sure that resonance and vibrations are properly managed. That’s why we pair our motors with matched drivers, so users can enjoy optimal performance out of the box.

Why Leadshine is Trusted by Automation Experts

What makes us unique is our ability to support customers not just with products but with application-focused guidance. We know that the same stepper motor sizes can behave differently under various loading and speed conditions, which is why we prioritize testing and feedback in real-world environments. Leadshine has worked with thousands of engineers across industries, helping them achieve better machine performance with the right cnc stepper motor choices.

Conclusion

As we continue to serve professionals in automation, we remain focused on delivering the balance of innovation, performance, and reliability. Choosing the right stepper motor sizes and sourcing a dependable cnc stepper motor can transform a system's efficiency and reliability. At Leadshine, we are committed to helping you make informed decisions that align with your design goals and performance needs. Let's build something remarkable together—motor by motor, step by step.