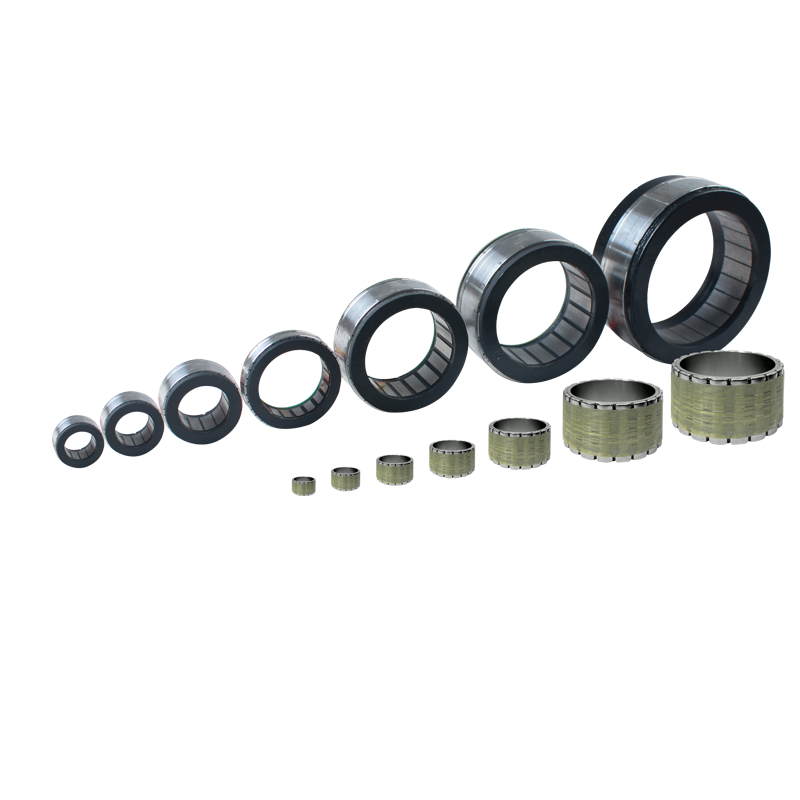

Our AC servo drives, especially the EL6 Series, guarantee excellent performance and accurate motion control in a range of applications. However, following recommended maintenance practices is crucial to extending the lifespan and effectiveness of our AC servo drives as well as the servo motor control system as a whole.

Regular Inspections and Cleanings

One of the most effective ways to maintain Leadshine's AC servo drives is by incorporating regular inspections and cleaning into your routine. Over time, dust, dirt, and other debris can accumulate within the servo motor control system, potentially affecting performance. We recommend scheduling routine inspections every three to six months, depending on the operating environment.

During these inspections, it's crucial to check for any signs of wear or damage to connectors, wires, and mounting components. A thorough cleaning should be performed using non-abrasive materials to avoid damaging sensitive components. By ensuring that the hardware is clean and free from contaminants, businesses can reduce risks associated with overheating and electrical issues, thereby prolonging the life of the AC servo drive.

Monitoring Temperature and Environmental Conditions

Temperature control is vital to maintaining the performance of our AC servo drives. The EL6 Series is designed to operate efficiently within specified temperature ranges; however, extreme temperatures can lead to reduced functionality and potential failures. To mitigate these risks, we advise implementing a temperature monitoring system in environments where heat generation may be a concern.

In addition to temperature, it is important to consider other environmental factors such as humidity and vibrations. High humidity levels can promote corrosion, while excessive vibrations can lead to mechanical wear. By creating an optimal working environment and regularly monitoring conditions, businesses can ensure their servo motor control system operates effectively and reliably.

Updating Firmware and Software Regularly

Leadshine's AC servo drives benefit from continuous improvements to firmware and software, which enhance functionality and fix known issues. Therefore, it is crucial to stay informed about updates relevant to your EL6 Series drive. Regularly updating the firmware not only improves performance but also ensures compatibility with evolving industry standards.

We suggest setting reminders to check for updates at least once every few months. Additionally, keep records of configuration settings before initiating any changes, allowing for straightforward restoration if needed. This proactive approach will help businesses maintain system integrity, optimize performance, and streamline the overall operation of the servo motor control system.

Conclusion

Diligence and attention to detail are necessary for the maintenance of Leadshine's AC servo drives. Businesses may extend the life and functionality of their servo motor control systems by implementing effective practices like routine cleaning and inspections, temperature and environmental monitoring, and firmware updates. Reliability and performance will increase significantly over the years if you invest in proper maintenance now.